Khoom Configuration

Lub ci ci cub coil cua sov lub caij yog ib hom tshwj xeeb ntawm qhuav-hluav taws kub cua sov raj tsim los rau qhov kub thiab txias ib puag ncig. Lub tshuab hluav taws xob qhuav hluav taws xob cua sov yog hais txog lub tshuab hluav taws xob cua sov uas ua haujlwm ncaj qha rau saum huab cua yam tsis muaj kev sib cuag nrog cov kua.Qhov tsim ntawm qhov cub coil cua sov ua kom nws khiav ruaj khov rau lub sijhawm ntev nyob rau hauv qhov kub thiab txias thaum tsis txhob xeb lossis kev puas tsuaj los ntawm cov kua xov xwm.

Los ntawm qhov kev xav ntawm cov qauv sab hauv, lub hauv paus tseem ceeb ntawm lub qhov cub coil cua sov lub caij yog tsim los ntawm cov xov hlau cua sov uas tau teem rau hauv cov qauv kauv. Cov qauv kauv no tsis yog tsuas yog ua kom cov cua sov tso tawm xwb tab sis kuj tseem txhim kho lub zog txhua yam ntawm lub caij. Txawm tias nyob rau hauv tej yam kev mob ntawm high-frequency vibration los yog huab cua hloov, cov cua kub nyob ntawm tej tsis tshua muaj feem yuav tawg los yog tsis. Ntxiv mus, vim yog siv cov khoom siv kub-resistant thiab oxidation, qhov nruab nrab kev pab cuam lub neej ntawm xws li cua sov cov ntsiab lus tuaj yeem ncav cuag 3000 teev, ua rau lawv zoo heev rau cov khoom siv hauv tsev lossis cov khoom siv hluav taws xob uas yuav tsum tau ua haujlwm ntev.

Los ntawm qhov pom ntawm qhov pom, qhov tsis kam ntawm qhov cub qhov cub coil cua sov hauv lub qhov cub feem ntau yog ua los ntawm tshwj xeeb kho qhov tob ntsuab stainless hlau. Qhov no stainless hlau nto yog muab cov xim ntsuab sib sib zog nqus los ntawm cov txheej txheem "annealed". Yog li ntawd, thaum peb qhib lub qhov cub hauv peb lub neej txhua hnub, peb yuav pom tias cov cua sov sab hauv yog qhov sib sib zog nqus ntsuab es tsis txhob muaj cov xim npub uas cov hlau zoo tib yam tig tom qab oxidation. Cov yam ntxwv no tsis tsuas yog txhim kho kev zoo nkauj tab sis kuj qhia tau hais tias cov khoom muaj cov khoom zoo heev los tiv thaiv oxidation, uas tuaj yeem ua tau zoo rau kev pab cuam lub neej ntawm qhov cub coil cua sov.

Khoom Paramenters

| Khoom npe | Ci Element Replacement Parts Electric Oven Coil Heating Element |

| Humidity State Insulation Resistance | ≥200MΩ |

| Tom qab Humid Heat Test Insulation Resistance | ≥30MΩ |

| Humidity State Leakage Current | ≤0.1mA |

| Nto Load | ≤3.5W / cm2 |

| Tube txoj kab uas hla | 6.5mm, 8.0mm, 10.7mm, thiab lwm yam. |

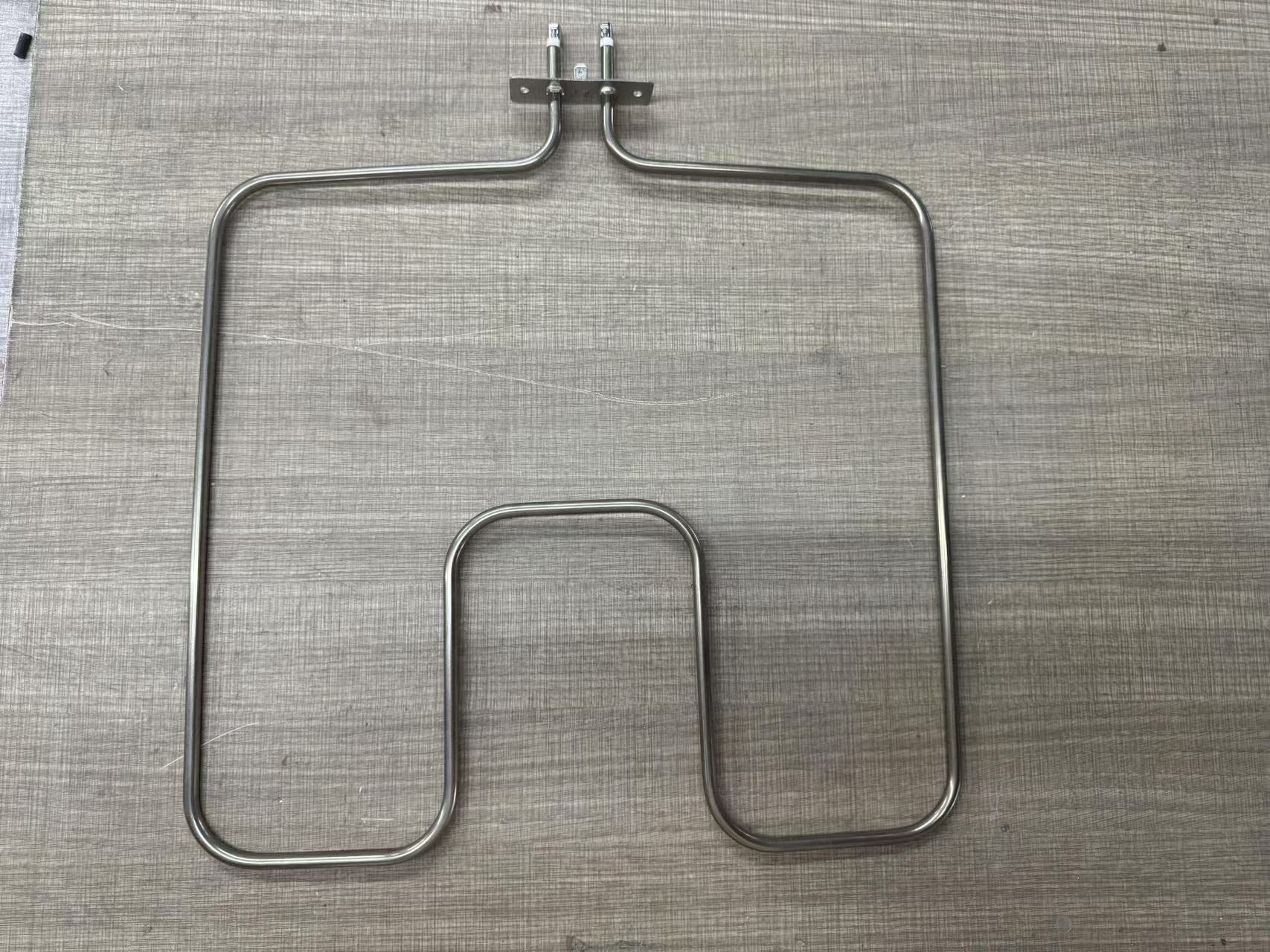

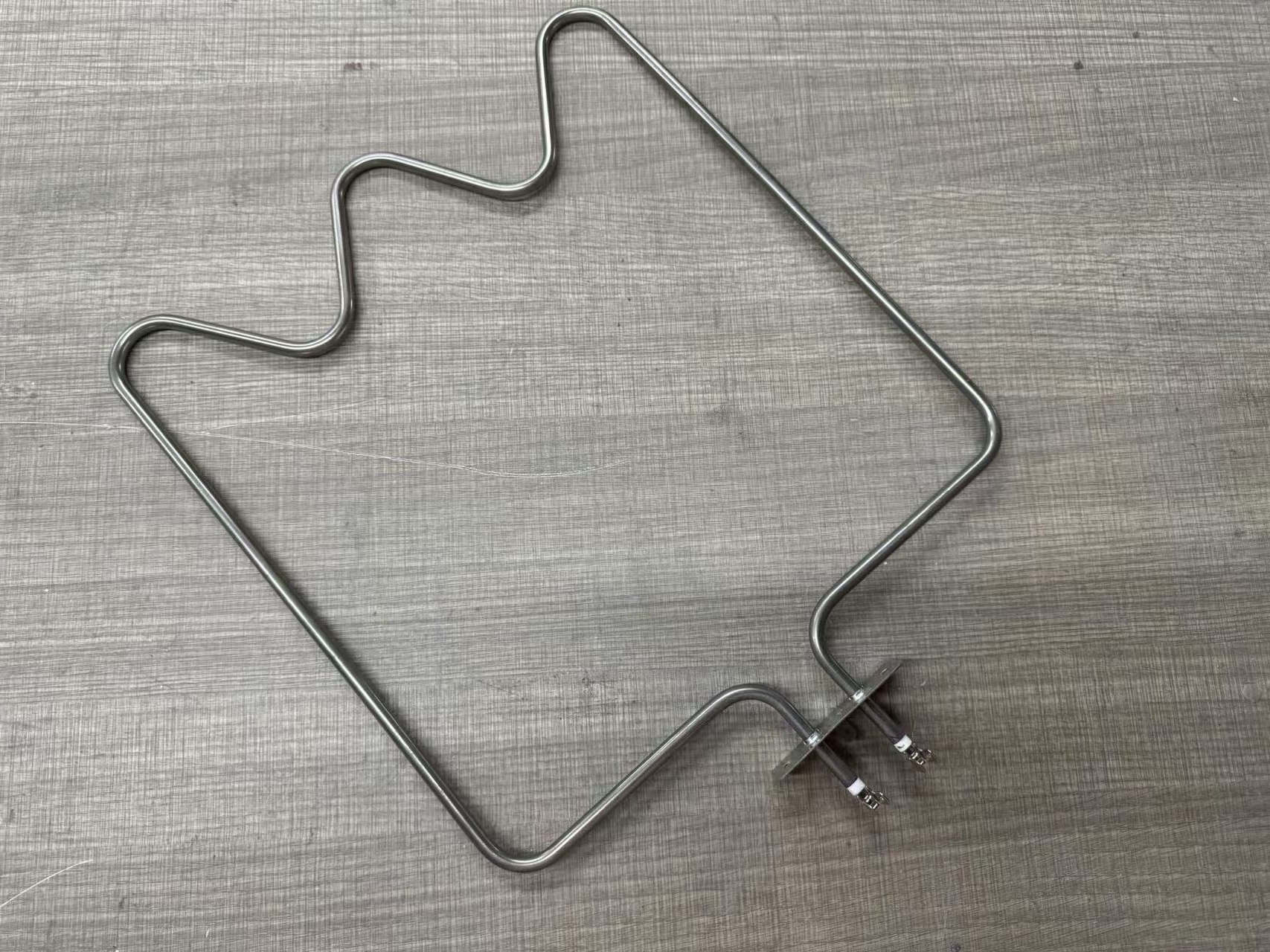

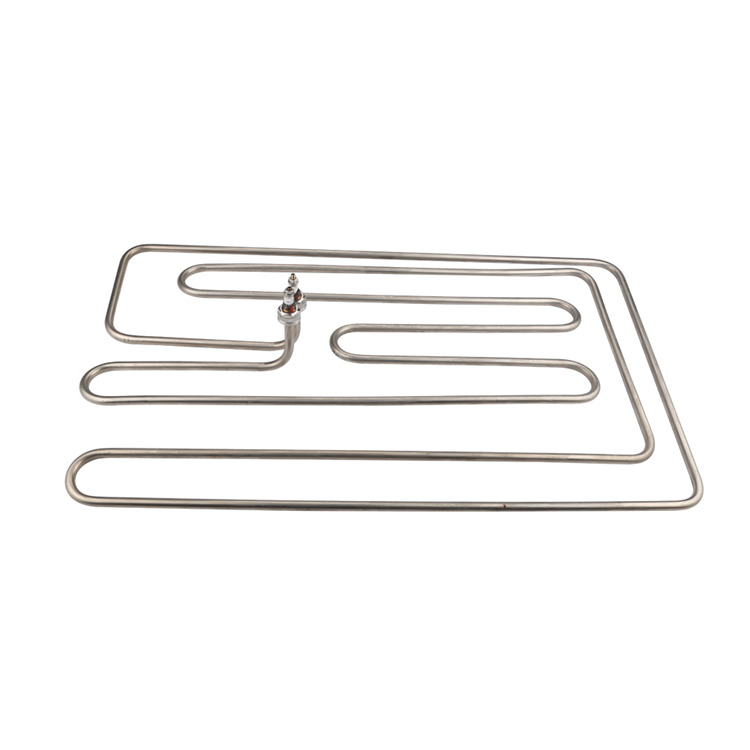

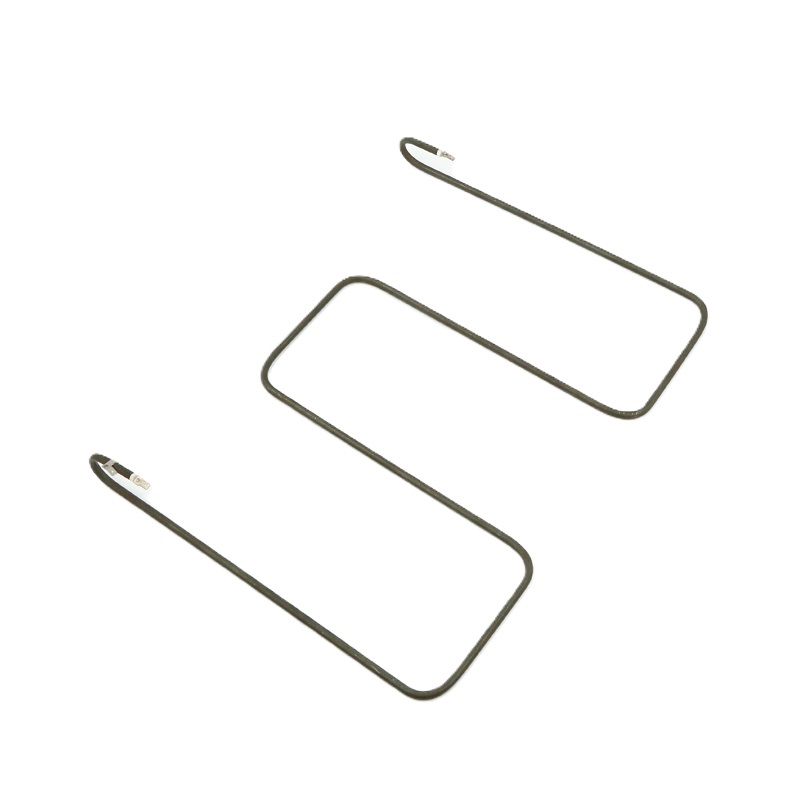

| Cov duab | ncaj, U puab, W puab, thiab lwm yam. |

| Resistant voltage | 2,000V / min |

| Insulated tiv thaiv hauv dej | 750 hmo |

| Siv | Qhov cub Coil Heating Element |

| Tube ntev | 300-7500 hli |

| Cov duab | customized |

| Kev pom zoo | CE / CQC daim ntawv pov thawj |

| Tuam txhab | Hoobkas / chaw tsim khoom / chaw tsim khoom |

| Lub tubular qhov cub coil cua sov lub tshuab rhaub yog siv rau lub microwave, qhov cub, hluav taws xob grill.Cov duab ntawm lub qhov cub rhaub lub raj tuaj yeem hloov kho raws li tus neeg siv khoom kos duab lossis cov qauv.Lub raj txoj kab uas hla tuaj yeem xaiv 6.5mm, 8.0mm lossis 10.7mm. JINGWEI HEATER yog cov kws tshaj lij cua sov raj Hoobkas / chaw tsim khoom / chaw tsim khoom, qhov hluav taws xob thiab lub zog ntawmqhov cub cua sov elementRau cov hniav nyiaj hniav kub / cub / microwave tuaj yeem kho raws li qhov yuav tsum tau ua.Thiab qhov cub cua sov lub raj tuaj yeem muab tshem tawm, lub raj xim yuav tsaus ntsuab tom qab annealing.Peb muaj ntau yam qauv ntawm lub davhlau ya nyob twg, yog tias koj xav tau ntxiv lub davhlau ya nyob twg, koj xav tau xa peb tus qauv ua ntej. | |

Khoom nta

Cov qauv tsim sib txawv no txhawm rau txhim kho cov khoom siv hluav taws xob kom zoo dua qub thiab hloov mus rau qhov yuav tsum tau muaj ntawm ntau qhov cub sab hauv. Piv txwv li, U-shaped thiab W-shaped designs tuaj yeem ua kom ntev ntev ntawm cov cua sov hlau los txhim kho cov khoom siv hluav taws xob hauv ib cheeb tsam, yog li ua tiav cov cua sov zoo dua.

Cov khoom siv

Qhov cub coil cua sov cov ntsiab lus yog qhov tseem ceeb hauv ob qho tib si hauv tsev thiab chaw tsim khoom, lub luag haujlwm tsim cov cua sov uas xav tau rau kev ua noj, ci, thiab ntau yam kev lag luam. Nyob rau hauv qhov chaw qhov cub, qhov cub ci qhov cub cua sov cov ntsiab lus feem ntau pom muaj xws li ci (hauv qab) thiab broil (sab saum toj) cov ntsiab lus, nrog rau cov qhov cub convection kuj suav nrog cov kiv cua thiab cov cua sov rau cov cua sov.

JINGWEI Rhiav

Txheej txheem ntau lawm

Kev pabcuam

Txhim kho

tau txais cov khoom specs, kos duab, thiab duab

Cov lus hais

tus thawj tswj xyuas cov lus nug hauv 1-2 teev thiab xa cov lus hais

Cov qauv

Cov qauv dawb yuav raug xa mus rau kev kuaj xyuas cov khoom zoo ua ntej bluk ntau lawm

Ntau lawm

paub meej cov khoom specification dua, ces npaj cov khoom

Kev txiav txim

Muab qhov kev txiav txim thaum koj paub tseeb cov qauv

Kev sim

Peb pab pawg QC yuav raug kuaj xyuas cov khoom zoo ua ntej xa khoom

Ntim

packing cov khoom raws li xav tau

Chaw thau khoom

Thauj khoom npaj rau cov neeg siv khoom lub thawv

Txais

Tau txais koj xaj

Vim Li Cas Xaiv Peb

•25 xyoo exporting & 20 xyoo kev tsim khoom

•Factory npog thaj tsam ntawm 8000m²

•Hauv xyoo 2021, txhua yam khoom siv ntau lawm tau hloov pauv, suav nrog cov hmoov filling tshuab, yeeb nkab shrinking tshuab, yeeb nkab dabtsi yog khoov khoom, thiab lwm yam.

•qhov nruab nrab txhua hnub tso zis yog txog 15000pcs

• Cov neeg siv khoom sib txawv

•Customization nyob ntawm koj qhov kev xav tau

Daim ntawv pov thawj

Yam khoom

Lub Hoobkas duab

Ua ntej qhov kev nug, pls xa peb cov lus qhia hauv qab no:

1. Xa peb cov duab kos lossis duab tiag tiag;

2. Lub rhaub loj, lub zog thiab qhov hluav taws xob;

3. Tej yam tshwj xeeb yuav tsum tau ntawm lub rhaub.

Hu rau: Amiee Zhang

Email: info@benoelectric.com

Wechat: +86 15268490327

WhatsApp: +86 15268490327

Skype: amiee19940314