| TSIS MUAJ. | Khoom | Chav tsev | Qhov Qhia | Cov Lus Cim |

| 1 | Qhov Loj thiab Geometry | mm | Ua raws li cov neeg siv kos duab xav tau |

|

| 2 | Kev hloov pauv ntawm tus nqi tsis kam | % | ≤ ± 7% |

|

| 3 | Kev tiv thaiv rwb thaiv tsev ntawm chav tsev kub | MΩ | ≥100 | tus tsim tsa |

| 4 | Lub zog rwb thaiv tsev ntawm chav tsev kub |

| 1500V 1 feeb Tsis muaj kev puas tsuaj lossis flashover | tus tsim tsa |

| 5 | Kub ua haujlwm (ib 'meter' ntawm qhov ntev ntawm cov hlau) tam sim no xau | mA | ≤0.2 | tus tsim tsa |

| 6 | Lub zog txuas ntawm lub davhlau ya nyob twg | N | ≥50N1min Tsis txawv txawv | Sab saud ntawm cov xov hlau |

| 7 | Lub zog txuas nruab nrab | N | ≥36N 1 feeb Tsis txawv txawv | Nruab nrab ntawm cov xov hlau cua sov thiab cov xov hlau |

| 8 | Kev tuav txoj kab uas hla ntawm lub raj txhuas | % | ≥80 |

|

| 9 | Kev sim ntau dhau |

| Tom qab qhov kev sim, tsis muaj kev puas tsuaj, tseem ua tau raws li qhov yuav tsum tau ua ntawm Tshooj 2,3 thiab 4 | Ntawm qhov kub ua haujlwm tso cai |

| Tam sim no ntawm 1.15 zaug ntsuas voltage rau 96 teev |

1. Kev tiv thaiv ntawm cov av noo hauv lub xeev ≥200MΩ

2. Qhov dej ntws tawm tam sim no ≤ 0.1mA

3. Qhov chaw thauj khoom ≤3.5W / cm2

4. Kub ua haujlwm: 150 ℃ (siab tshaj 300 ℃)

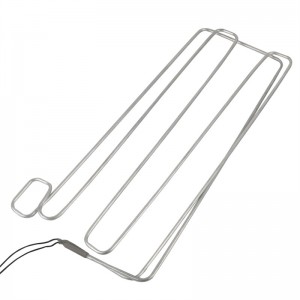

1. Kev teeb tsa yooj yim.

2. Hloov cua sov sai.

3. Kev kis tau hluav taws xob kub ntev.

4. Muaj zog tiv thaiv kev xeb.

5. Tsim thiab tsim los rau kev ruaj ntseg.

6. Tus nqi pheej yig nrog kev ua haujlwm zoo thiab lub neej ua haujlwm ntev.

Cov khoom siv cua sov raj txhuas yooj yim dua rau siv hauv qhov chaw kaw, muaj peev xwm hloov pauv zoo heev, hloov kho tau rau txhua hom chaw, muaj kev ua haujlwm zoo heev, thiab txhim kho cov cua sov thiab yaj.

Nws feem ntau siv los yaj thiab tswj cua sov rau lub tub yees, lub tub yees, thiab lwm yam khoom siv hluav taws xob.

Nws qhov ceev ceev ntawm cua sov thiab kev sib luag, kev ruaj ntseg, los ntawm thermostat, lub zog ceev, cov khoom siv rwb thaiv tsev, qhov kub hloov, thiab cov xwm txheej cua sov tawg tuaj yeem tsim nyog ntawm qhov kub thiab txias, feem ntau yog rau defrosting tub yees, defrosting lwm yam khoom siv hluav taws xob cua sov, thiab lwm yam kev siv.